Salem

This facility is located on 2.75 acres and all operations are inside a 20,000 sq. ft. building with 8 bulk tanks used for custom blending. We have 4 blending tanks ranging from 280 gallons to 1,200 gallons. We currently use 15-gallon returnable/refillable closed system drums and 5-gallon cubes as our main containers. We also have 15-gallon one-way drums and 250-gallon IBC totes available. This facility warehouses and sales package vegetation management chemical and adjuvants to our retail customers across the country and is involved in forestry application project across western United States.

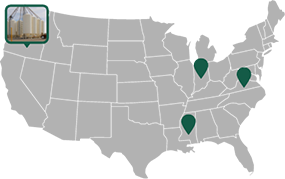

4175 Salem Industrial Drive NE.

Salem, OR. 97301